Mass Balance Explained

What is mass balance?

Mass balance is a basic principle in science and chemical engineering. Manufacturing units use this approach to achieve circular or bio-economy, which involves tracking the flow of materials into and out of a system to ensure that mass remains conserved. This concept is especially useful for analyzing processes and sustainability features of bio or circular materials and bookkeeping.

Mass balance follows the law of conservation of mass, which states that mass cannot be created or destroyed in a closed system. By utilizing this principle, one can account for all system inputs, outputs, and accumulations. The process helps identify inefficiencies in the entire system, optimize processes, and ensure proper compliance with environmental regulations.

In practical applications, the mass balance formula is used to create and evaluate treatment processes, manage waste, and estimate the environmental impact of industrial activities (circularity). For example, in wastewater treatment, mass balance calculation helps determine the amount of pollutants removed from water and the overall efficiency of the entire treatment process.

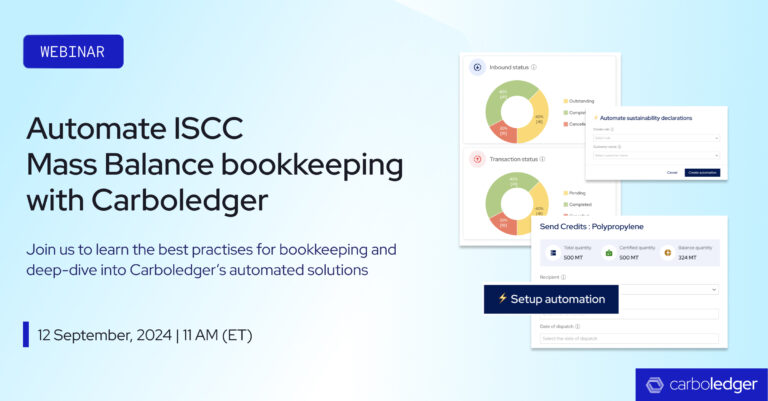

What is the ISCC mass balance approach?

The mass balance approach defined by ISCC is a fundamental method used in the chemical industry to ensure that mass is being conserved within a closed system. This approach utilizes the law of conservation of mass. The mass balance approach helps in tracking the flow of materials in a closed system.

In application terms, the mass balance approach involves considering all inputs, outputs, generation, and consumption of materials. The mass balance formula ensures that all material flows are accurately maintained, making it possible to enhance the overall process. The mass balance approach is widely used in industries such as chemical engineering, environmental management, and manufacturing.

Understanding the mass balance approach is important for developing sustainable practices and improving overall process efficiency. By accurately accounting for material flows, industries can improve resource utilization, reduce environmental footprints, and enhance process efficiency.

ISCC mass balance approach for sustainable material tracking

The ISCC (International Sustainability and Carbon Certification) mass balance approach is important for tracking the flow of sustainable materials. This approach is essential, especially for industries that aim to transition into a circular economy and reduce their reliance on fossil fuels.

The mass balance approach allows for the mixing of certified and non-certified materials within the same production process. The approach ensures that the amount of sustainable material entering the system is accurately calculated. This method is particularly valuable in industries where physical segregation of materials is impractical or economically unfeasible.

The ISCC mass balance approach has various key advantages, one of which is its flexibility. It enables companies to gradually increase the proportion of sustainable and recyclable stock in their production processes. This incremental approach helps scale up the use of sustainable materials without impacting overall manufacturing operations.

In practice, the ISCC mass balance approach involves detailed tracking and documentation of material flows. Companies are required to maintain records of inputs and outputs, ensuring that the sustainability of the materials are preserved throughout the process. This transparency is important for making claims about the sustainability of the final products.

Chain of custody and mass balance

Chain of custody is the process of tracking raw materials from start to end during the entire process of supply chain; this includes material at source, in transit, shipping, and retail.

The chain of custody also referred to as CoC and mass balance are important concepts in supply chain management which ensures transparency and accountability. The chain of custody is basically a documented process that tracks the movement of raw materials through various stages of the supply chain i.e., production, processing, and distribution. It guarantees that the materials are handled according to specified standards, maintaining their traceability.

On the other hand, the ISCC mass balance approach is used to account for the quantity of materials entering and leaving a closed system, ensuring that the inputs match the outputs. This technique is essential for verifying the accuracy of material flows and detecting any discrepancies in the entire process.

The relationship between chain of custody and mass balance is vital for industries aiming to achieve sustainability and regulatory compliance. By integrating these two concepts, businesses can ensure that their supply chains are not only efficient but also transparent and trustworthy. This integration helps identify potential issues, improve resource management, and enhance overall operational efficiency.

Mass balance approach in chemical recycling

In chemical recycling, the mass balance approach involves tracking the flow of recycled and sustainable materials through the production process. This method allows for the mixing of chemically recycled and conventional materials, ensuring that the recycled content is accurately accounted for. The main approach here is to maintain a balance between the input and output of recycled materials.

The mass balance approach has a widespread adoption in the chemical industry. It supports the tracking of sustainable materials through complex supply chains, ensuring transparency and sustainability.

The mass balance approach for chemical recycling involves detailed documentation and certification processes. Overall, the mass balance approach in chemical recycling involves a step toward more sustainable production practices.

The bottom line

Energy and mass balance are fundamental principles in engineering and environmental science that ensure efficient and sustainable operations. By carefully accounting for the flow of energy and materials within a system, this approach helps in identifying inefficiencies of a system, optimizing resource use, and minimizing overall environmental impacts. The application of energy and mass balance is important for creating sustainable practices, enhancing process efficiency, and complying with environmental as well as regulatory standards.

There is a shift in industries toward a circular economy, therefore understanding and implementing mass balance calculations and approach becomes increasingly important. By using energy and mass balance principles, companies can improve their sustainability index, reduce waste, and contribute to a more environment friendly future. Applying these concepts in the production process not only supports environmental conservation but also accelerates economic benefits through improved operational efficiency and resource management.

Disclaimer:

Carboledger Inc. is an independent software provider. References to ISCC or any other certification schemes in this article are made solely for informational and educational purposes. Carboledger is not affiliated with, certified by, or endorsed by ISCC System GmbH or any certification body. The content does not constitute certification advice or official guidance.