In the realm of chemical manufacturing, where accuracy and sustainability converge, mass balance stands as a crucial concept. Fundamentally, mass balance involves the rigorous tracking of sustainable material inputs, outputs, and accumulations within a production system.

The mass balance approach ensures the transition to a sustainable future and helps organizations achieve their sustainability goals. Besides its technical importance, mass balance plays a vital role in enhancing and cultivating connections between chemical manufacturers and their customers.

Today, in the highly competitive market, customer relationships are beyond transactions; they are strongly based on transparency, trust, and shared values. Customers in the chemical sector are growing more concerned with the sustainability and ethical conduct of the businesses they choose to engage with. Mass balance is a key factor in addressing these concerns.

By embedding mass balance into their operations, chemical manufacturers can showcase their commitment to sustainability and transparency, thereby enhancing their relationships with customers. This blog will examine the fundamentals of mass balance, its role in account management, and how it can be leveraged to generate value and strengthen customer connections.

What is mass balance?

Mass balance is a fundamental principle that entails accounting for all mass entering and exiting a system to ensure that the total mass remains consistent over time. The principle of mass balance is grounded in the law of conservation of mass, which states that matter cannot be created or destroyed, only transformed. In the context of chemical manufacturing, mass balance methodology is utilized to procure and sell sustainable materials to help customers achieve their sustainability goals.e

The role of mass balance in strengthening customer relationships

In the chemical industry, maintaining a consistent and strong relationship becomes crucial for long-term success. To meet sustainability objectives, mass balance plays an important role in the complete process of providing a framework for accountability and transparency. Chemical manufacturers can develop sustainable solutions and enhance customer trust by embedding mass balance into their account management strategies.

In the present scenario, customers are increasingly prioritizing products that are both high in quality and sustainable; chemical manufacturers can leverage mass balance principles to monitor the use of eco-friendly materials, like recycled feedstocks, throughout the production process. This allows manufacturers to offer customers deep insights into the sustainability of the products they choose to purchase, boosting customer satisfaction as well as loyalty.

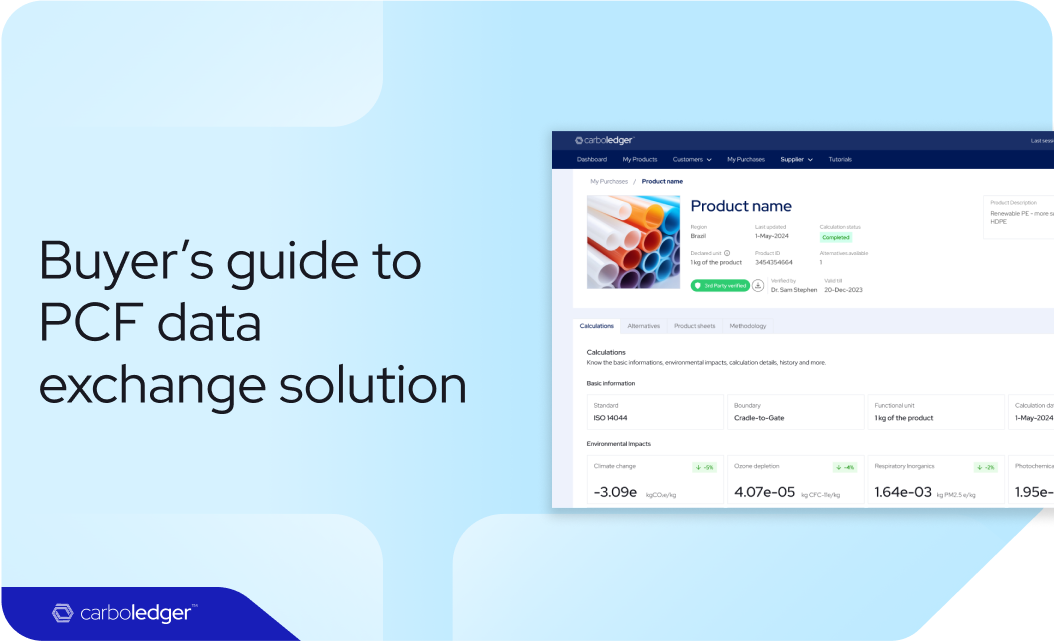

Furthermore, mass balance can be integrated into customer relationship management (CRM) systems to provide real-time data on product carbon footprint or life cycle assessment of the products. By providing a satisfactory level of transparency, chemical manufacturers can differentiate themselves from competitors and position themselves as trusted partners in sustainability.

The role of mass balance in enhancing customer value

Mass balance not only provides a cost-effective method for developing sustainable materials, but it also plays a pivotal role in delivering value to the customers. As sustainability becomes a prime focus in the chemical industry, mass balance offers a structure for the joint creation of eco-friendly products. Manufacturers can ensure their products align with sustainability standards customers demand by tracking material and resource flow throughout the production process.

In the creation of bio-based chemicals, mass balance helps verify the bio-based content in the final product, enabling manufacturers to deliver certified sustainable solutions. Through the collaboration of sustainable products, chemical manufacturers can foster stronger, more cooperative relationships with their customers rooted in shared values and objectives.

Enhancing credibility is a significant benefit of integrating mass balance into customer relationships. In an industry where greenwashing – making misleading environmental claims is a rising concern, mass balance provides a dependable way to substantiate sustainability assertions. By offering transparent and verifiable data on resource consumption and product composition, chemical manufacturers can build customers’ trust, establishing themselves as reliable and trustworthy sustainability partners.

Supply chain transparency is another important area where mass balance can deliver substantial value. In today’s interconnected market, customers are increasingly interested in knowing the origins and manufacturing processes of their products. The mass balance enables chemical manufacturers to monitor material flow across the supply chain, allowing them to provide customers with detailed information about product origins and composition. This transparency not only enhances the overall value of the products but also strengthens customer trust.