In a time where sustainability is a prime concern, mass balance has become a crucial tool for industries striving to develop sustainable solutions. Through diligent tracking and balancing of material inputs and outputs, mass balance facilitates companies in achieving more efficient and transparent management of sustainable materials. However, with the increasing complexity of supply chains and heightened sustainability demands, the traditional mass balance approach is being stretched to its breaking point. In this blog, we explore the future of mass balance, focusing on the innovations and technologies that promise to revolutionize this essential practice.

Already adopted in various industries with complex supply chains, the mass balance approach is a flexible and scalable method. It is a well-established chain of custody model that evolves as a promising way to advance circularity. Innovation and emerging technologies have swiftly become important topics in the sustainability space, especially in the petrochemical and plastic industries.

What is mass balance: A brief overview

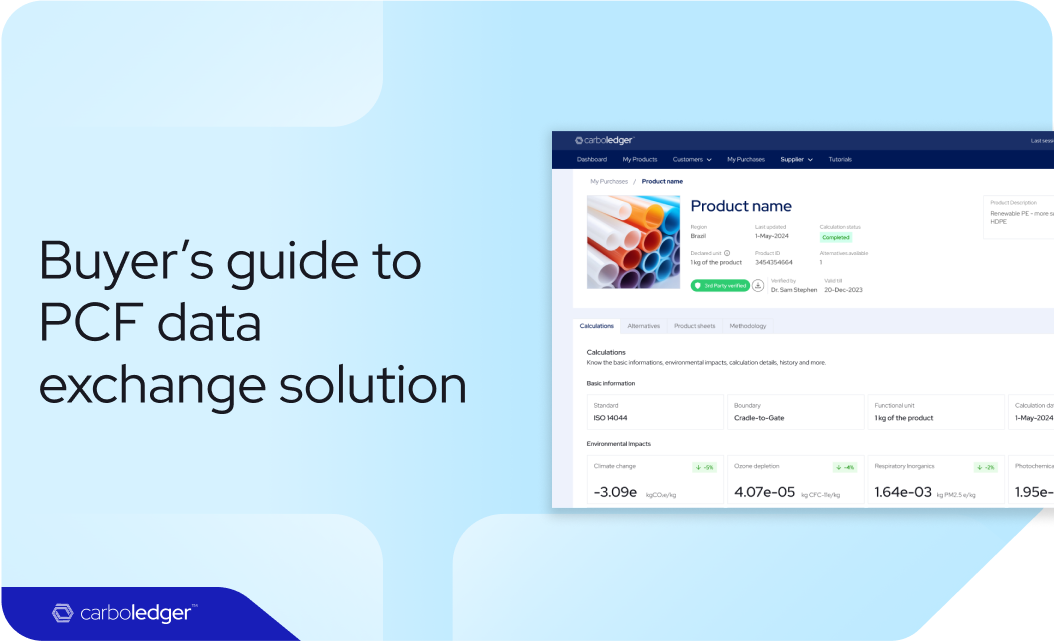

Within a production system, mass balance is a method used to manage and track the flow of materials, making sure that the inputs (raw material) and the outputs (finished products) are balanced. The concept of mass balance, at its core, is a principle rooted in the law of conservation of mass as it ensures that the mass entering and the mass exiting remains the same, whether in the form of products, by-products, or waste.

In the chemical industry, manufacturers often replace a portion of fossil-based feedstocks with recycled or bio-based materials without making any changes to the existing setup, showcasing a practical application of mass balance. This strategy ensures an accountable approach to tracking how much of the final product is derived from sustainable sources, even when raw materials are mixed during the production process.

The need for innovation

While the core principles of mass balance remain unchanged, the environment in which they are applied has evolved dramatically. Supply chains have become more complicated, with materials often traveling across multiple continents and passing through various stages. Moreover, the rising consumers’ demand has also put immense pressure on companies to provide accurate and verifiable mass balance data. These above-mentioned challenges highlight the need for innovation in mass balance methodologies, especially in the fields of data integration, sustainability, and automation.

Limitations and obstacles in current mass balance approaches

In the present complex industrial landscape, the traditional mass balance approach, while effective in simpler systems, faces significant challenges. Traditional methods employ manual interventions, making it difficult for companies to respond swiftly to changes in production or supply chain conditions. One of the prominent challenges is the dependency on manual data collection and processing, which leads to inconsistencies, errors, and delays.

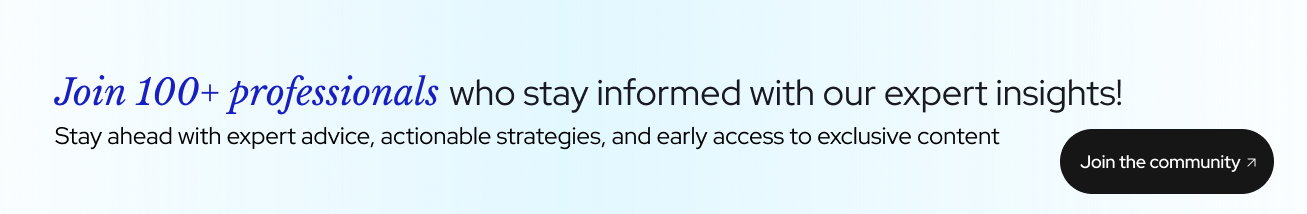

Another significant limitation is the difficulty in integrating mass balance with other critical business systems, such as Enterprise Resource Planning (ERP) systems. In the absence of seamless integration, companies may struggle to automate mass balance for scaling sustainable portfolios, limiting its value as a tool for strengthening efficiency and sustainability.

The role of automation in simplifying mass balance calculations

The recurring challenge of human error in the areas of maintaining consistency and accuracy in mass balance calculations can be significantly reduced by automating data collection and processing. The transformative potential of automation will play a critical role in surmounting these challenges. Automated systems are capable of handling large volumes of data in a much more efficient manner as compared to manual methods, enabling real-time reporting and monitoring.

To illustrate, artificial intelligence can read supplier declarations for transferring inbound credits and create sustainable declarations to share with customers. By integrating with ERP, costly errors and delays such as conversion factor calculation and overallocation can also be avoided, reducing time spent in managing mass balance bookkeeping.